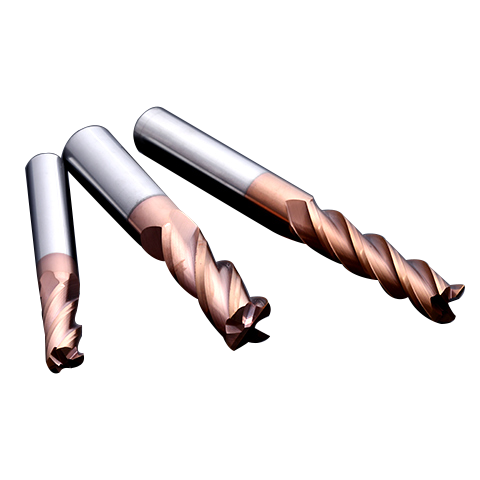

HM HRC65 Square End Mills 4 Flute

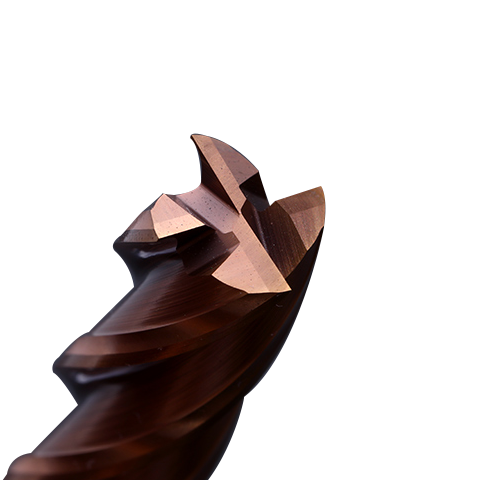

- Raw material: with 12% Co content and 0.2-0.3um grain sizee, high hardness, and high toughness

- Coating: AlTiSiN, with the hardness and thermal stability are up to 4000HV and 1200℃, respectively

- Tolerance of End Mill Diameter: 1 < D≤6 -0.010 ~ -0.030;6 < D≤10 -0.015 ~ -0.040;10 < D≤20 -0.020 ~ -0.050

Features

- 4 flutes, high rigidity, widely used in shallow slot, profile milling, and finish machining.

- 2 helix angle is 45deg, high adaptability to material and hardness of work pieces, widely used to mold and product processing and cost efficient.

Products Categories

Get A Free Quote

HRC65 Square End Mills 4 Flute Description

- Place of Origin: Guangdong, China

- Brand Name: NANZHI TOOLS

- Model Number: ≤HRC65

- Material: Carbide

- Stock: Rich

- Processing Type: Metal Cutting Tools

HM HRC65 Square End Mills 4 Flute

| Recommended Parameters | |

| Cutting speed | Vc=130(120-180)m/min |

| Depth of cut | Ap=1/3D(1/8-1/2D) |

| Cutting width | Ae=1/2D(1/4-1D) |

| Single-edge feed | Fz=0.15mm(0.02-0.2) |

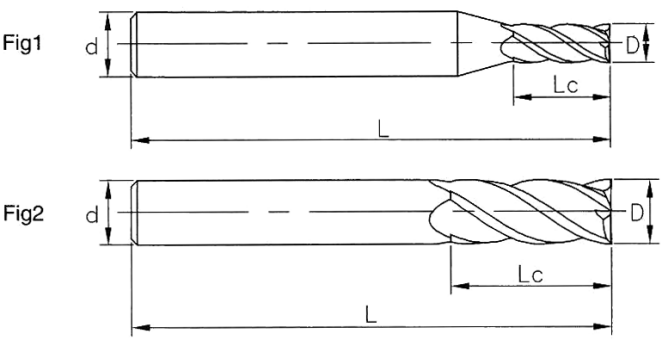

| Square End mill | ||||||

| Cat.No | DIA | Lc | Shank | OVL | Flutes | Figure No. |

| 3*8*3*50 | 3 | 8 | 3 | 50 | 4 | 2 |

| 3*12*3*75 | 3 | 12 | 3 | 75 | 4 | 2 |

| 3*15*3*100 | 3 | 15 | 3 | 100 | 4 | 2 |

| 1*3*4*50 | 1 | 3 | 4 | 50 | 4 | 1 |

| 1.5*4*4*50 | 1.5 | 4 | 4 | 50 | 4 | 1 |

| 2*5*4*50 | 2 | 5 | 4 | 50 | 4 | 1 |

| 2.5*7*4*50 | 2.5 | 7 | 4 | 50 | 4 | 1 |

| 3*8*4*50 | 3 | 8 | 4 | 50 | 4 | 1 |

| 3.5*10*4*50 | 3.5 | 10 | 4 | 50 | 4 | 1 |

| 4*10*4*50 | 4 | 10 | 4 | 50 | 4 | 2 |

| 4*16*4*75 | 4 | 16 | 4 | 75 | 4 | 2 |

| 4*20*4*100 | 4 | 20 | 4 | 100 | 4 | 2 |

| 5*13*5*50 | 5 | 13 | 5 | 50 | 4 | 2 |

| 5*20*5*75 | 5 | 20 | 5 | 75 | 4 | 2 |

| 5*25*5*100 | 5 | 25 | 5 | 100 | 4 | 2 |

| 2.5*7*6*50 | 2.5 | 7 | 6 | 50 | 4 | 1 |

| 3*8*6*50 | 3 | 8 | 6 | 50 | 4 | 1 |

| 3.5*10*6*50 | 3.5 | 10 | 6 | 50 | 4 | 1 |

| 4*10*6*50 | 4 | 10 | 6 | 50 | 4 | 1 |

| 4.5*12*6*50 | 4.5 | 12 | 6 | 50 | 4 | 1 |

| 5*13*6*50 | 5 | 13 | 6 | 50 | 4 | 1 |

| 6*15*6*50 | 6 | 15 | 6 | 50 | 4 | 2 |

| 6*25*6*75 | 6 | 25 | 6 | 75 | 4 | 2 |

| 6*30*6*100 | 6 | 30 | 6 | 100 | 4 | 2 |

| 6*40*6*150 | 6 | 40 | 6 | 150 | 4 | 2 |

| 7*18*8*60 | 7 | 18 | 8 | 60 | 4 | 1 |

| 8*20*8*60 | 8 | 20 | 8 | 60 | 4 | 2 |

| 8*28*8*75 | 8 | 28 | 8 | 75 | 4 | 2 |

| 8*35*8*100 | 8 | 35 | 8 | 100 | 4 | 2 |

| 8*50*8*150 | 8 | 50 | 8 | 150 | 4 | 2 |

| 9*23*10*75 | 9 | 23 | 10 | 75 | 4 | 1 |

| 10*25*10*75 | 10 | 25 | 10 | 75 | 4 | 2 |

| 10*40*10*100 | 10 | 40 | 10 | 100 | 4 | 2 |

| 10*50*10*150 | 10 | 50 | 10 | 150 | 4 | 2 |

| 11*28*12*75 | 11 | 28 | 12 | 75 | 4 | 1 |

| 12*30*12*75 | 12 | 30 | 12 | 75 | 4 | 2 |

| 12*45*12*100 | 12 | 45 | 12 | 100 | 4 | 2 |

| 12*60*12*150 | 12 | 60 | 12 | 150 | 4 | 2 |

| 14*35*14*80 | 14 | 35 | 14 | 80 | 4 | 2 |

| 14*45*14*100 | 14 | 45 | 14 | 100 | 4 | 2 |

| 14*60*14*150 | 14 | 60 | 14 | 150 | 4 | 2 |

| 16*45*16*100 | 16 | 45 | 16 | 100 | 4 | 2 |

| 16*60*16*150 | 16 | 60 | 16 | 150 | 4 | 2 |

| 18*45*18*100 | 18 | 45 | 18 | 100 | 4 | 2 |

| 18*70*18*150 | 18 | 70 | 18 | 150 | 4 | 2 |

| 20*45*20*100 | 20 | 45 | 20 | 100 | 4 | 2 |

| 20*70*20*150 | 20 | 70 | 20 | 150 | 4 | 2 |

Please adjust the parameters accroding to the material and hardness of work pieces.

| Recommended Cutting Speed Table | |||||||||||||

| Material Category | Strength | Hardness(HB/HRC) | Cutting Speed(m/min) | ||||||||||

| (N/mm²) | MIN | Recommended | MAX | ||||||||||

| P | Carbon Steel | <600 | <230 | 160 | 180 | 210 | |||||||

| Alloy Steel | <1200 | <350 | 120 | 160 | 180 | ||||||||

| High-Alloy Steel & Tool Steel | <1400 | <380 | 120 | 160 | 180 | ||||||||

| M | Austenitic-Ferritic Stainless Steel | <680 | <220 | 120 | 180 | 210 | |||||||

| Martensitic Stainless Steel | <820 | <380 | 100 | 120 | 160 | ||||||||

| K | Gray Cast Iron | <280 | 120 | 150 | 180 | ||||||||

| Ductile Iron | – | <320 | 90 | 110 | 130 | ||||||||

| N | Non-Ferrous Alloys | <250 | <110 | ||||||||||

| Aluminum Alloys | <530 | <130 | – | 一 | |||||||||

| S | Superalloys | <3300 | <350 | 40 | 60 | 80 | |||||||

| Titanium Alloys | <2100 | <400 | 70 | 90 | 110 | ||||||||

| H | High-Hardness Steel | <54HRC | 90 | 120 | 150 | ||||||||

| High-Hardness Steel | 54-60HRC | 90 | 110 | 130 | |||||||||

| High-Hardness Steel | – | >60 HRC | 70 | 90 | 110 | ||||||||

Get Free Quote of HM HRC65 Square End Mills 4 Flute

Packaging & Delivery

1.One plastic pipe pack one piece,10 pcs per group

2.Put goods enclosed with air bubble paper into box

3.Other package is accepted according to customer’s requirement

Shipment: UPS/Fedex/DHL/TNT/EMS/ect