Dongguan Nanzhi Carbide Technology Co., Ltd.

Nanzhi Cutting Tools: founded in 2017, specializes in the R&D, manufacturing, and distribution of CNC cutting tools.

For the past seven years, guided by our core belief that “Quality Speaks for Itself”, we have consistently prioritized excellence. This commitment enables us to deliver high-performance, cost-effective carbide cutting tools to our global user base.

Company Information

Strong R&D Focus

Our in-house research and development team comprises more than 60 specialists, driving continuous innovation.

Experienced Workforce

We employ a dedicated team of over 300 staff members.

Global Sales Network

Multiple dedicated sales teams ensure responsive service and support worldwide.

Extensive Inventory

Our warehouse stocks over 5,000 distinct product models.

Significant Inventory Investment

The total value of our on-hand inventory exceeds 100 million RMB (approx. $14 million USD).

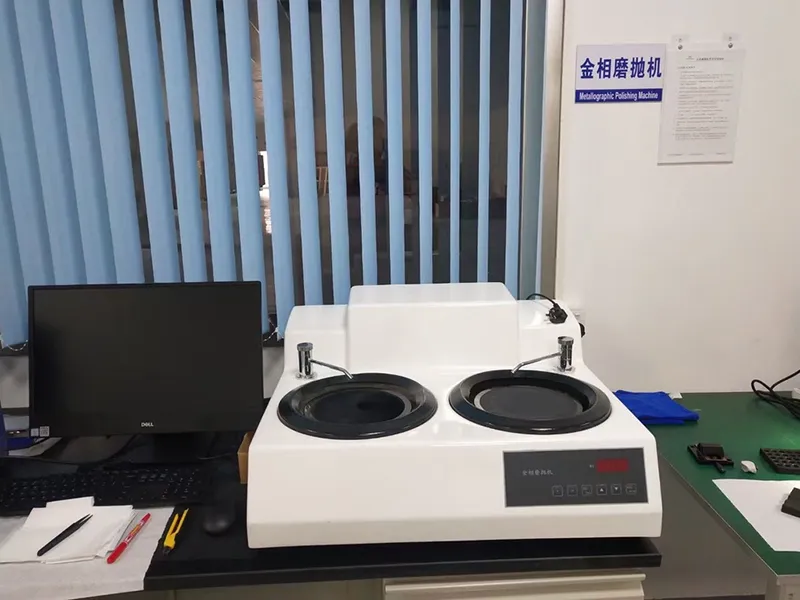

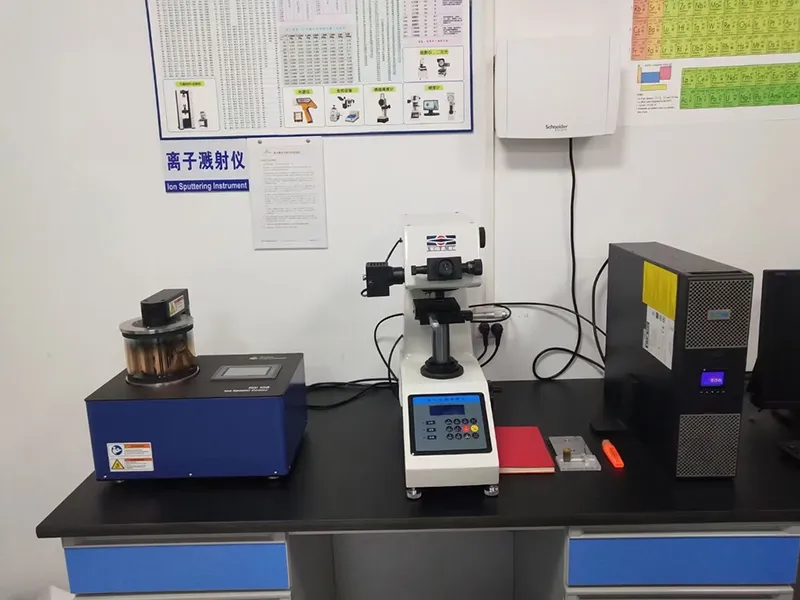

R&D Center

Our advanced facility is equipped with multiple critical instruments for materials analysis and tool development, including: Scanning Electron Microscopes (SEM), Metallographic Cut-Off Machines, Ion Sputter Coaters, Metallographic Grinding/Polishing Machines, Helium Mass Spectrometer Leak Detectors (HMLD), and other specialized equipment.

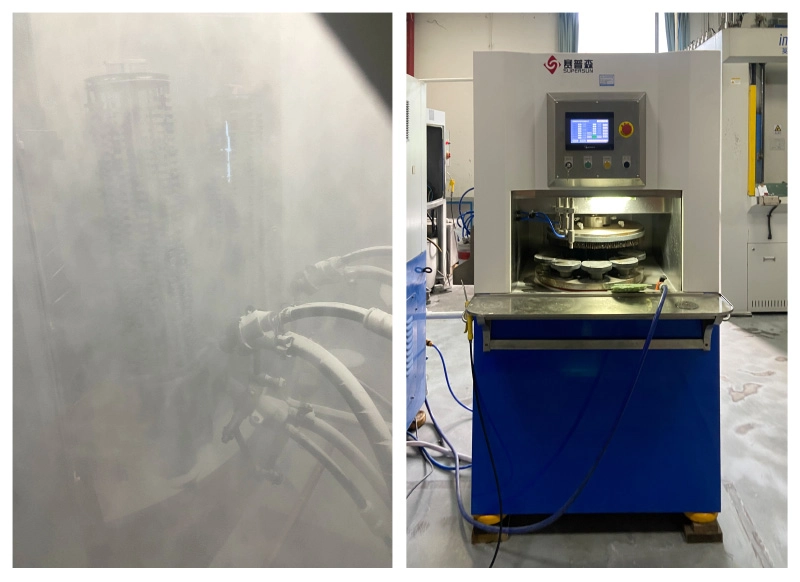

Production Workshop

We operate a fleet of 80 in-house developed PVD coating machines, showcasing our commitment to proprietary technology and scalable production.

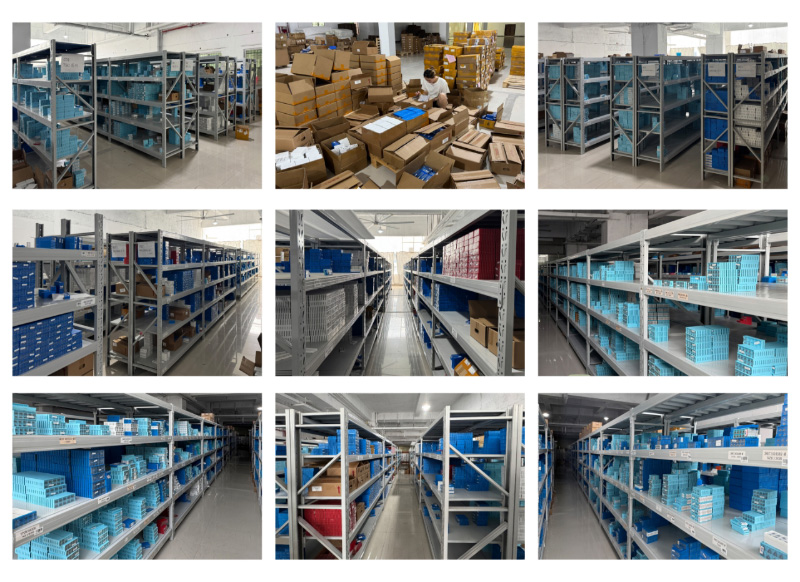

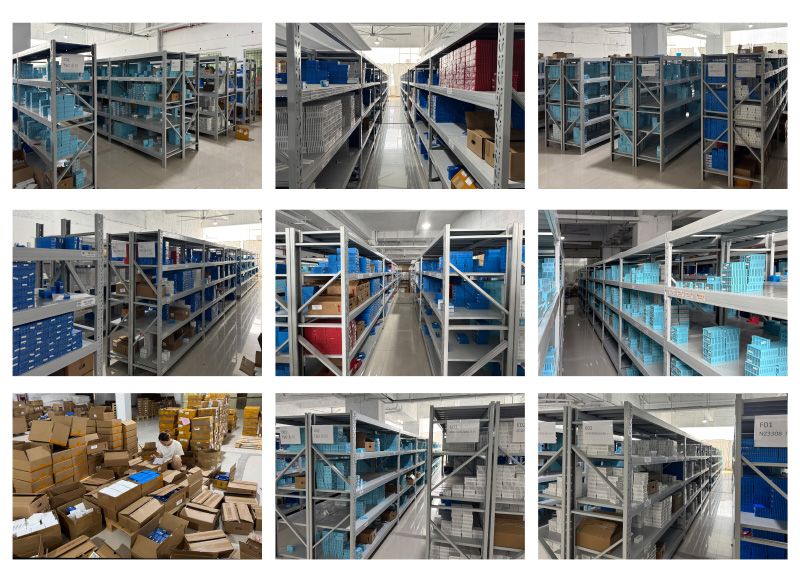

Warehouse & Authorized Sales Outlets

With 5,000+ product SKUs and ¥100 million (≈$14 million) inventory, we deliver comprehensive one-stop procurement solutions.

20 Authorized Sales Outlets

Cutting Tool Testing Center

We maintain our own dedicated Cutting Tool Testing Center. This in-house capability ensures the highest level of data accuracy and reliability for all performance evaluations.

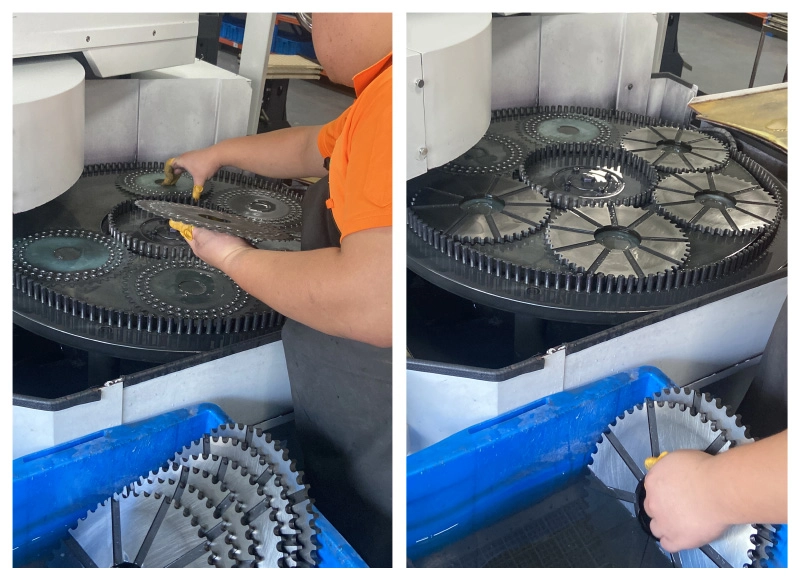

Advanced Finishing Lines

Our facility features a comprehensive suite of edge preparation processes, including:

Brush Honing、Face Honing、Blast Honing This integrated capability allows us to provide tailored post-processing solutions for virtually any insert requirement.