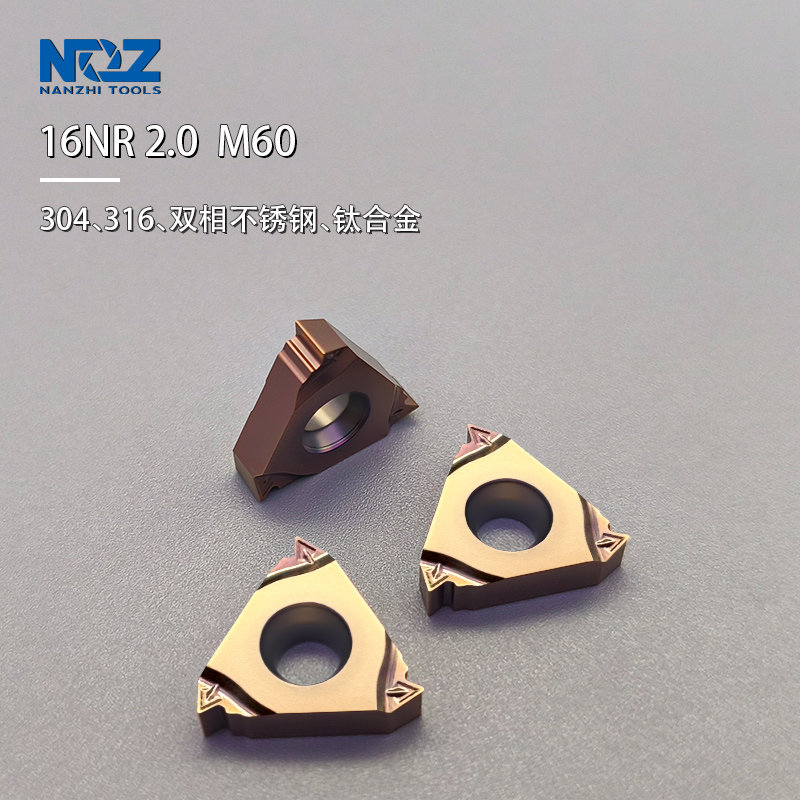

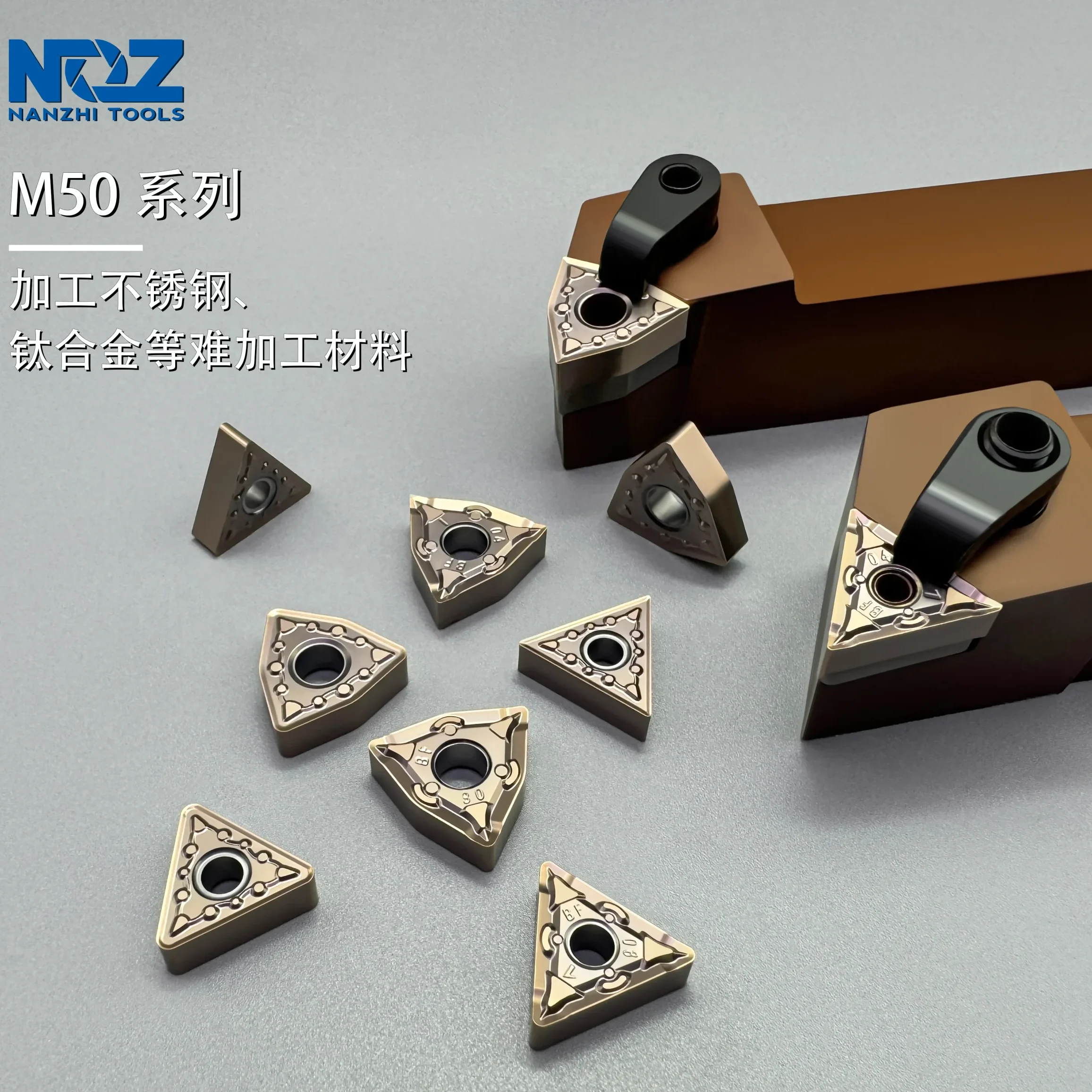

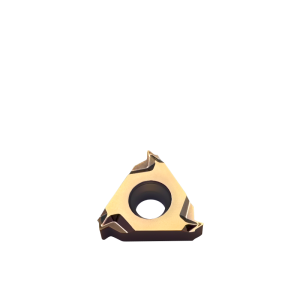

M60 Thread Inserts, Super Nano-Coating, 40GPa Hardness

Tailored for titanium/high-temp/nickel alloys. Super nano-coating fixes M-class gaps; 40GPa hardness + strong wear resistance boosts machining efficiency.

Key Features

- Core Specs: Super nano-coating (2.5μm), 40GPa hardness (outperforms standard inserts)

- Process Edge: Solves M-class process pain points

- Performance: High wear resistance, stable & efficient cutting

- Applications: Fits titanium/high-temp/nickel alloys (aerospace, precision manufacturing)

Products Categories

Get A Free Quote

Key Coating Properties

Hardness: Up to 40 GPa (exceptionally high)

Thickness: 2.5 μm

Performance Advantages:

Exceptional Hardness & Wear Resistance: Significantly extends tool life.

Dramatically Improved Machining Efficiency: Enables higher cutting speeds and feed rates.

Reduced Production Costs: Lower cost-per-part due to extended tool life and increased productivity.

M60 Difficult-to-Machine Carbide Insert Data Sheet

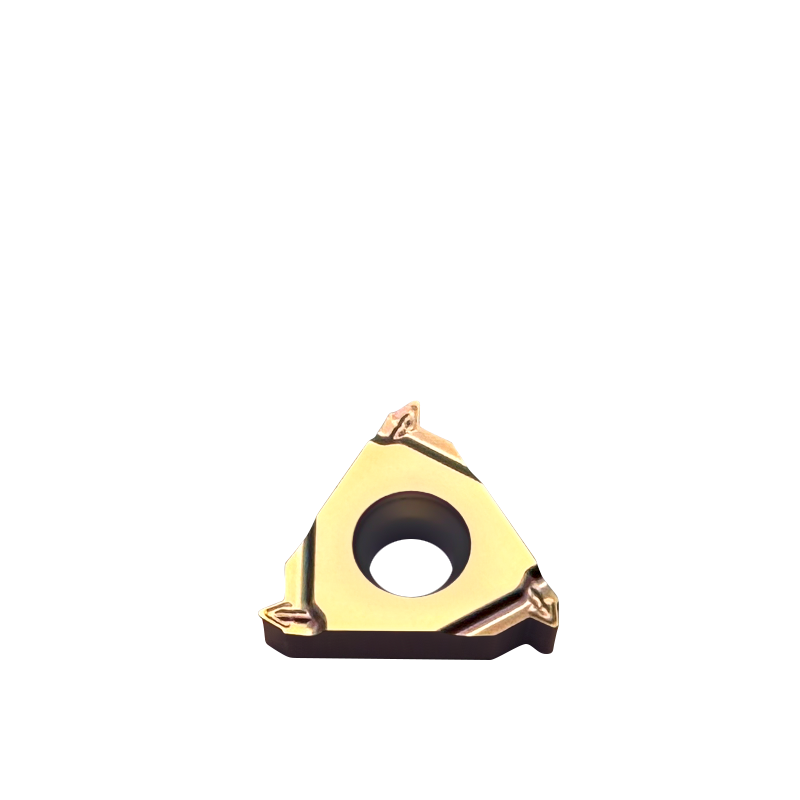

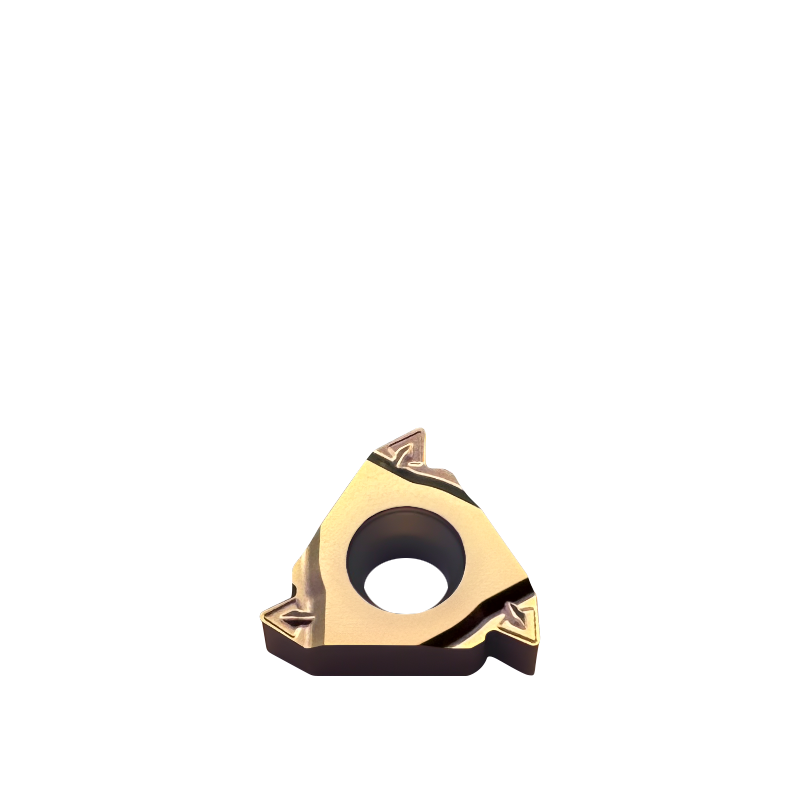

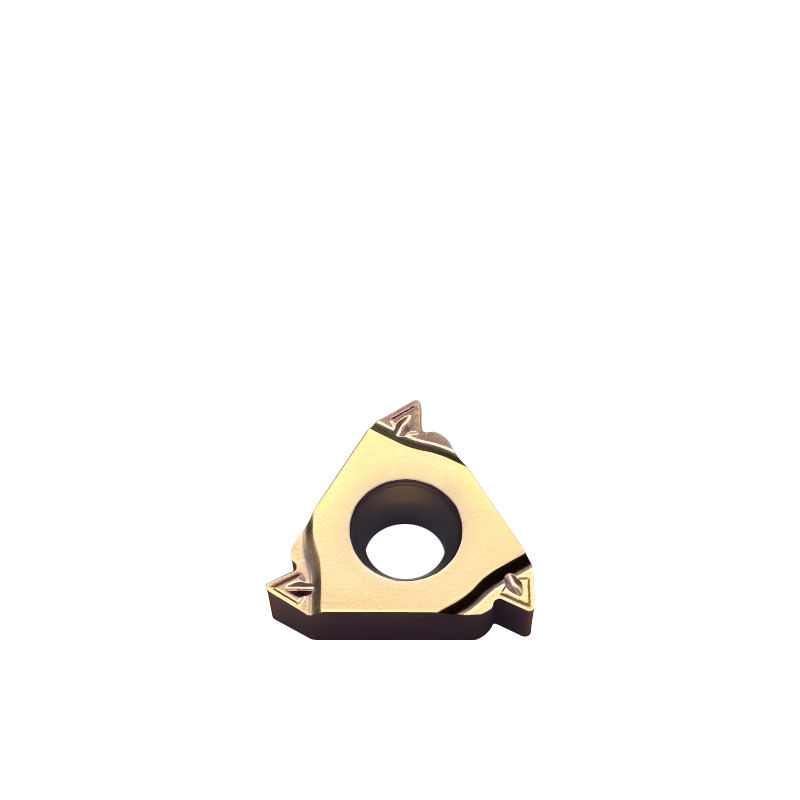

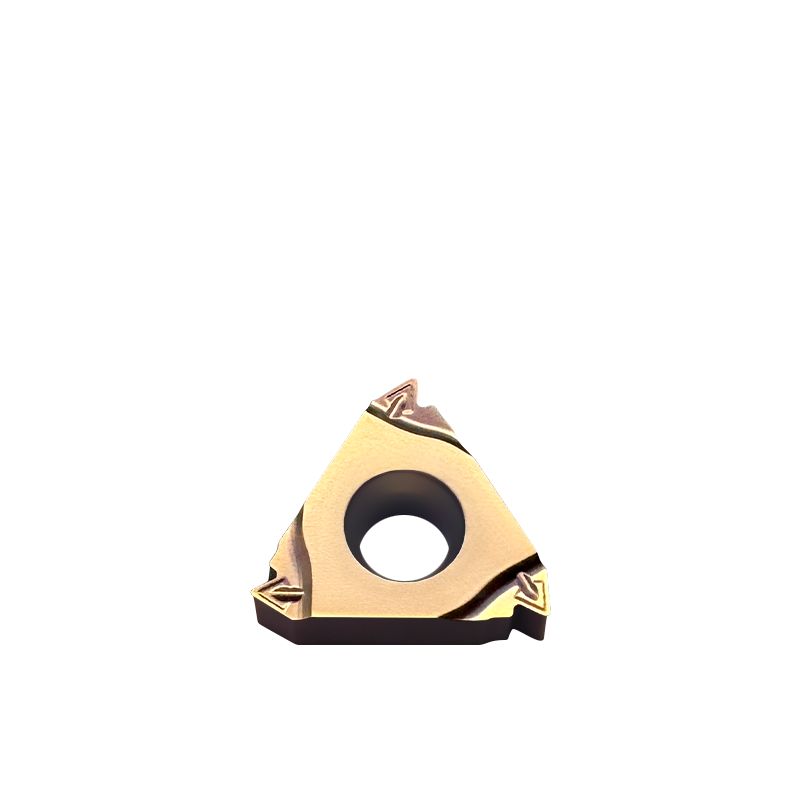

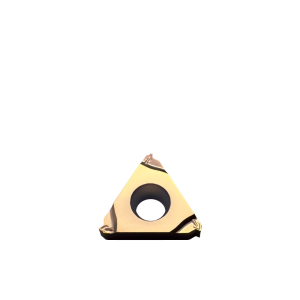

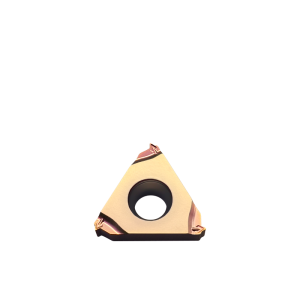

| M60 Thread insert | |||

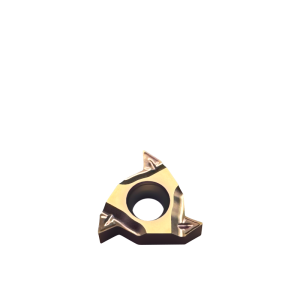

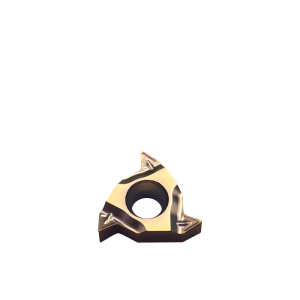

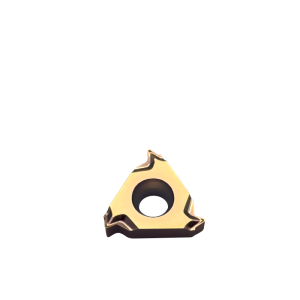

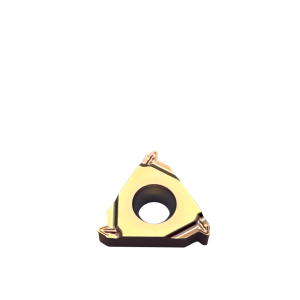

| model | Picture | model | Picture |

| 16ER 1.0 ISO |  |

16NR 1.0 ISO |  |

| 16ER 1.5 ISO | 16NR 1.5 ISO | ||

| 16ER 2.0 ISO | 16NR 2.0 ISO | ||

| 16ER 2.5 ISO | 16NR 2.5 ISO | ||

| 16ER 3.0 ISO | 16NR 3.0 ISO | ||

| 16ER AG60 |  |

16NR AG60 |  |

| 16ER AG55 |  |

16NR AG55 |  |

| 16ER 11W |  |

16NR 11W |  |

| 16ER 14W |  |

16NR 14W |  |